From metal materials to wire widths and color choices, we have now examined all the fundamental attributes of Round Wire and how to utilize them effectively in your jewelry designs. Now we can move from pen and paper to the workshop and start production!

…Well, almost.

Our design is almost ready to go, but we have one last thing to consider before we get our pliers ready—wire hardness.

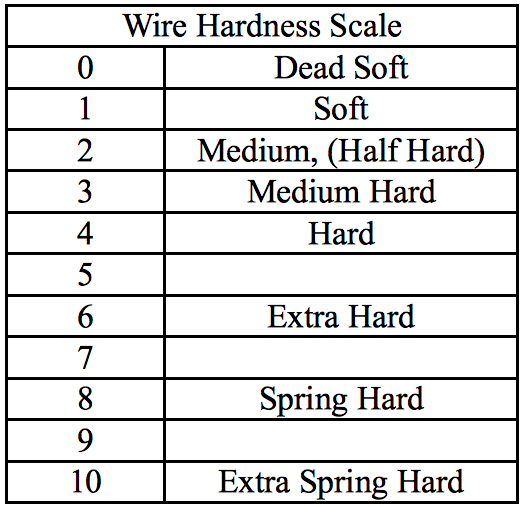

Wires are produced in a range of thicknesses on a 0 to 10 scale, 0 being “dead-soft” and 10 being “extra hard spring”. What we refer to as “hardness” is completely independent of thickness, it depends on the annealing process–how quickly the wire is cooled during manufacturing. The faster the wire is cooled during production, the more spring the final product has and vice versa. For jewelry purposes, especially with precious metal wire, it is uncommon to find wire higher than 4 on the hardness scale.

Hardness is probably the most overlooked and misunderstood wire attribute as the best choice depends on a number of general guidelines rather than rules set in stone. These guidelines will not directly affect the aesthetics of your finished piece, but it will certainly affect your ease of assembly, how clean the final product looks in the end, and how durable it is.

When to use dead soft, or soft wire

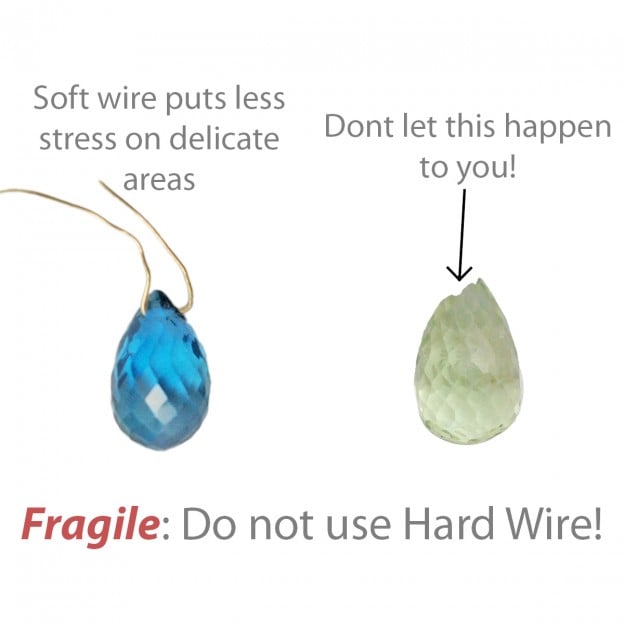

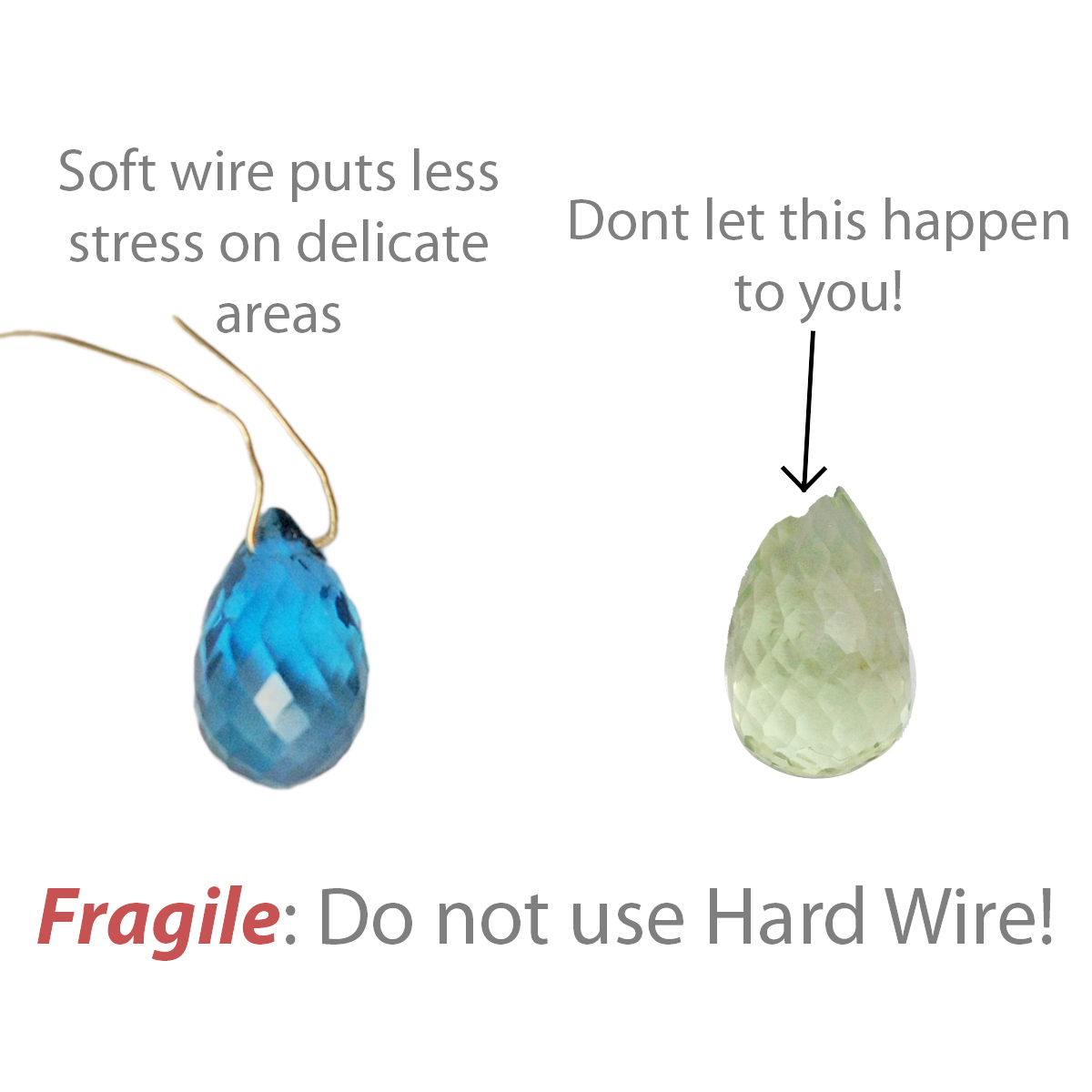

Softer temper wires are very flexible, being able to bend back and forth with little resistance but have the drawback of easily losing shape. Ideal uses for soft and dead soft wire include making detailed patterns or wrapping fragile drop shaped stones.

For most practical purposes, soft and dead soft temper wires of the same gauge are interchangeable. One caveat is that dead soft wire does not hold its shape as well, so you may need to wrap an extra coil or two when using thin gauges to ensure your piece holds securely. Unless you use metal wire to make weaves or crochet designs, this small distinction usually makes soft temper wire the better choice over dead soft wire.

What about harder wires?

As their names suggest, Half hard and Hard wire need more force to bend into shape. This extra durability makes it optimal for use with wire wrapped chains because hard wire can withstand more wear and tear and is far less likely to come undone than soft wire.

As I alluded to earlier, although harder temper wire makes more secure wraps, it is not suited for use with small drop shaped beads. When you bend your loops into place, the stiffness from the wire puts stress on the top of the bead which can cause briolettes, pear shaped, or heart shaped beads to crack.

What is the difference between half hard and hard wire?

Like comparing dead soft to soft temper, half hard and hard wires can be used similarly with small exceptions. Hard wire is better suited for designs which need to bear weight or will undergo significant of wear and tear like hand made earwires or studs. On the other hand, designers often prefer to make wire wrapped chains and centerpieces using half hard tempers because they have enough durability to keep its shape while still being easy to work with. A general rule of thumb is that the heavier gauge you use, the less hard your wire needs to be.

To sum everything up…

Wire hardness can be the difference between a piece being durable or flimsy, which makes weighing the benefits and drawbacks of each temper a crucial skill for seasoned designers. Hardness does not directly influence how your finished design will look, but it will certainly affect the ease with which you produce it.

Final thoughts on wires and your designs…

From the type of metal to its color, thickness and hardness, we have gone in depth over the major properties that will influence how you conceptualize and construct your wire jewelry project. Whether you are a novice designer or experienced wire worker, these three Wire Wrapping 101 articles hopefully have provided a fresh perspective on how to approach your designs.

If there is a single take away message on the subject, it is that there is much more to simple components like round wire than meets the eye. From linking chains, to hanging beads or weaving bracelets, we have just scratched the surface of the vast realm of design possibilities. Perhaps the easiest way to expand your range is in the form of round wire and a pair of pliers, so force yourself to test as many different wire types as you can, incorporate them into your work, and see where the spools take you.

-Cyrus Nemani, Gempacked